3D Laser Scanning Technology

Our advanced 3D scanning capability allows our specially trained technicians to visit your site to capture highly accurate measurements of existing machinery and components. This technology supports equipment assessment, reverse engineering, upgrades, and the manufacture of replacement parts—reducing downtime and eliminating guesswork.

Scroll down for more information or click here for more information

3D Laser Scanning Technology

3D Laser Scanning Technology

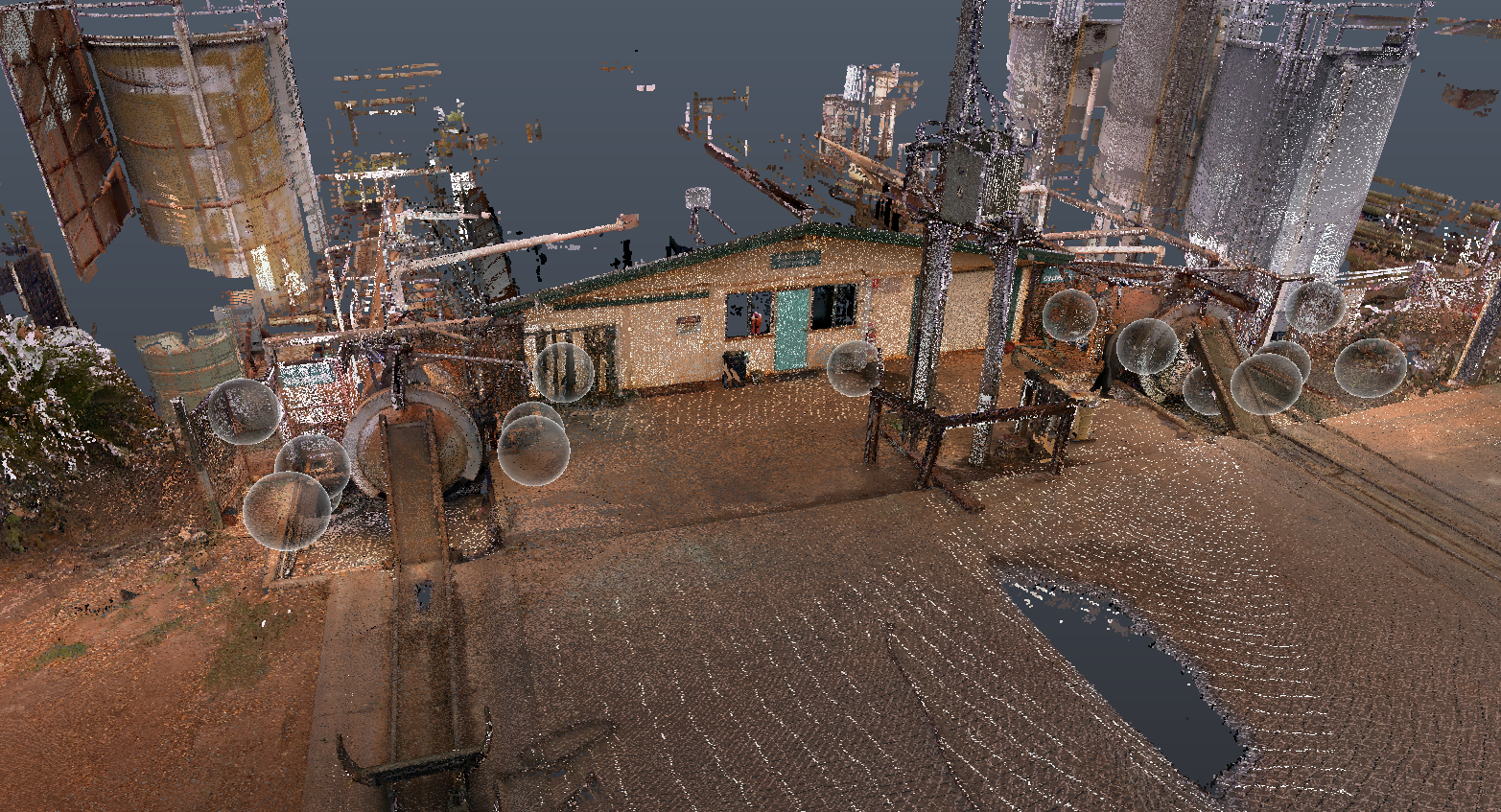

The innovative 3D scanning device is designed to capture a machine’s exact size and shape which is then displayed on a computer screen as a digital three-dimensional representation.

Using 3D laser scanning is like taking a picture but with more detail and depth, and the image can then be remodelled in the digital world and incorporated into CAD software packages such as Autodesk Inventor, Solid works and many others. It delivers a faster and more accurate approach to data collection and is a cost- effective approach for creating as-built layouts and dimensions of a facility.

What is 3D Laser Scanning:

The 3D laser scanner is a device that captures shapes of surrounding objects in a form of “point clouds” which means that all information becomes digitised. The data can then be utilised for modelling, designs, and much more. With laser scanning, we are capable of measuring a target in one day which would usually take many days or weeks using traditional methods. It can significantly reduce time required on sites, minimise risks and enhance operational efficiency. The 3D scanning and modelling can be used to create detailed digital models of factory and plant layouts, which can be used for planning and design and also for virtual reality experiences that permit workers to interact with digital models of the factory or plant in a safe and immersive way.

Benefits for Industrial Sites:

- Minimise shutdown times and the time required on site to capture measurements.

- Calculate the most complex industrial machinery and buildings accurately and quickly which is much more accurate than traditional methods.

- The 3D Laser scanning allows us to get measurements in hard-to-reach areas without putting someone in unsafe conditions.

- 3D laser scanning is a real breakthrough for industrial applications. Nowadays more companies utilise laser scanning for modern plant construction projects.

- Changes are always more costly at the end of a project than at the beginning. Making errors and having to redo them in retrospect must be avoided. 3D laser scanning is more cost-effective to simulate the factory in the digital environment.

- Our scanner boasts cutting-edge technology that enables the creation of lifelike 3D orbs during the scanning process. Each scan, referred to as a ‘station,’ captures a 360º photo, granting us the ability to immerse ourselves within the scanned environment. This high- definition photo allows for precise measurements and detailed examination, significantly enhancing the accuracy and utility of our scanning capabilities. Such advancements have the potential to revolutionize various industries, from architecture to virtual reality, offering new ways to document, visualize, and interact with physical spaces.

Reasons to use 3D Scanning

- Lack of existing drawings for machinery and site

- Modifications to equipment have not been documented

- Modernisation and remodelling of existing machinery and buildings

- Relocation of the whole plant

- Investigation of hazardous plant

Contact us for further information

Engineering Specialist Machinery

AE Gibson and Sons specialises in the design, manufacture and supply of specialist machinery.

Process Renewables and Waste

We help our customers to process renewable resources, biomass and waste products.

The NSW Construction Industry

We also support the construction industry on the Mid North Coast of NSW.

Contact AE Gibson and Sons for the Australian Engineering Service and Support That You Can Rely On. (02) 6559 4001